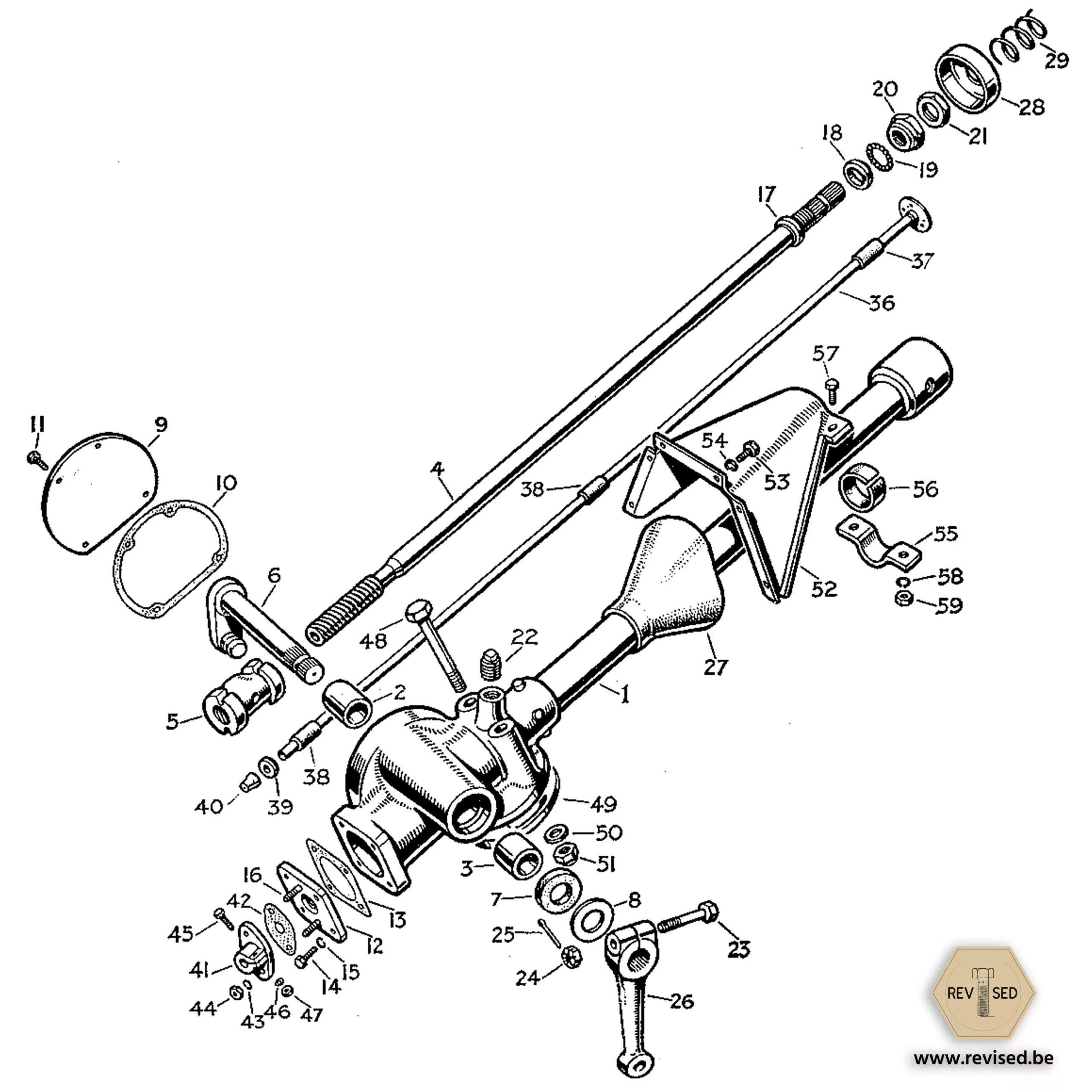

Steering box overhaul and restoration

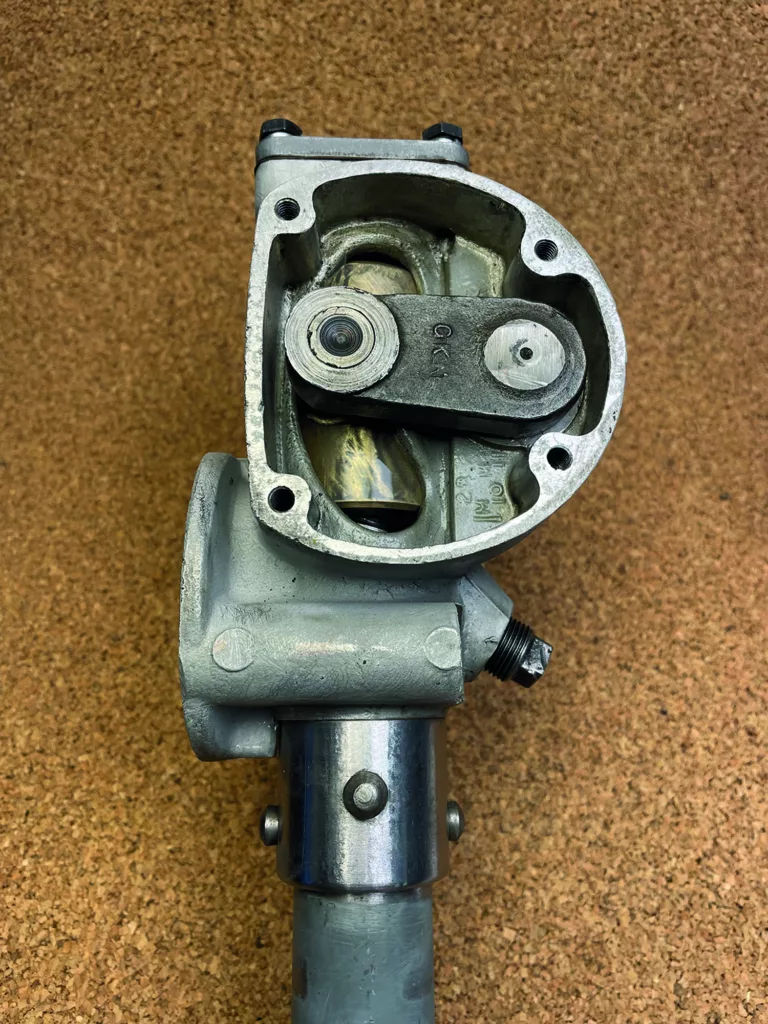

The steering box that was used on the Land Rover Series 1 80″ was a design by Burman Douglas, who produced steering boxes for various car manufacturers in the 1950’s.

These boxes were put trough a lot of stress during the service life of the early Land Rovers and some flaws in the design mean that most of them need to be refurbished after 75 years of service.

Although we can offer a rebuild service for all steering boxes of the various models on the Land Rover, we describe here the details for the aluminium version that was used on the 80″ in the early 1950’s. Do you have any other model of box that needs reconditioning, get in touch so we can offer you the best advice on how to proceed and on pricing.

Steering box overhaul

The Burman Douglas steering boxes show several flaws after years of service.

Excessive play on the steering wheel, resulting in a really vague behaviour, wear on the rocker arm bushes and cracking of the aluminium collar of the casing are the most common problems that we encounter. Combined with poor or non-existent lubrication of the box, this accelerates the wear of the components.

After a good amount of engineering and testing and cooperation between our in team in Belgium and our specialist colleague in the UK, we can now finally offer an excellent overhauled steering box which will last for many years and has all the known issues eliminated.

Overhaul procedure

After reception of your old steering box, this is carefully examined and measured. It is completely dismantles, cleaned and all parts are sandblasted to give a clean start.

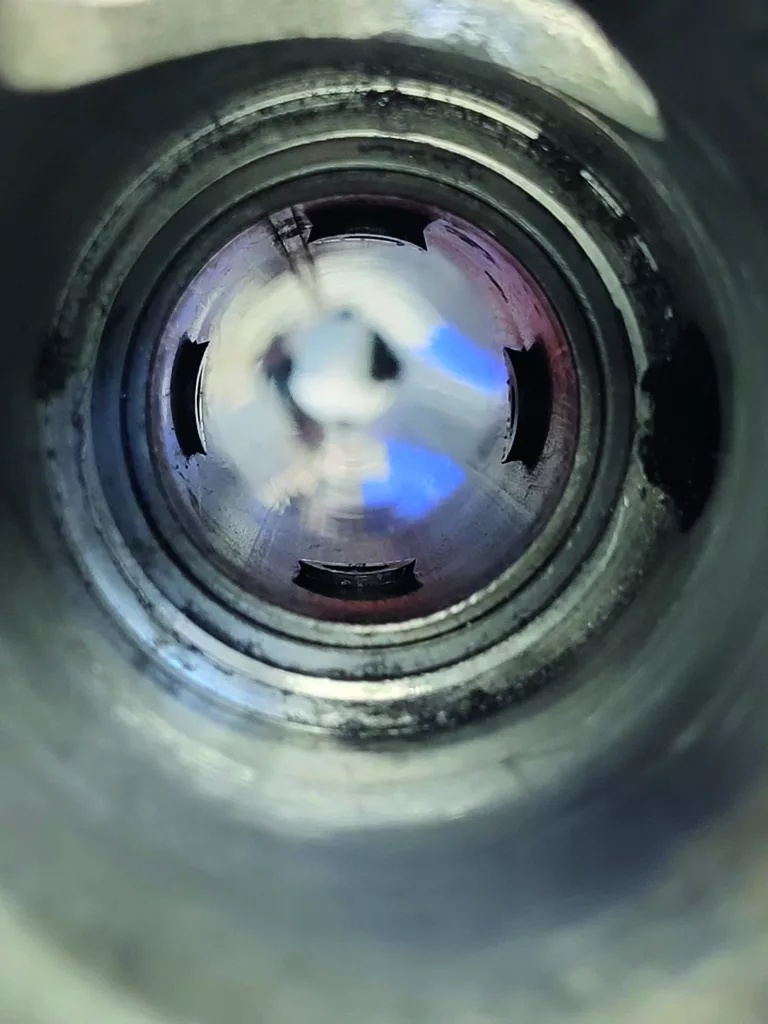

Most of the aluminium steering boxes have small cracks on the collar, where the steel tube is inserted in the alundum casing. Although they may not be very obvious at first, they will only get bigger during the life of the box and because of the forces applied to this area.

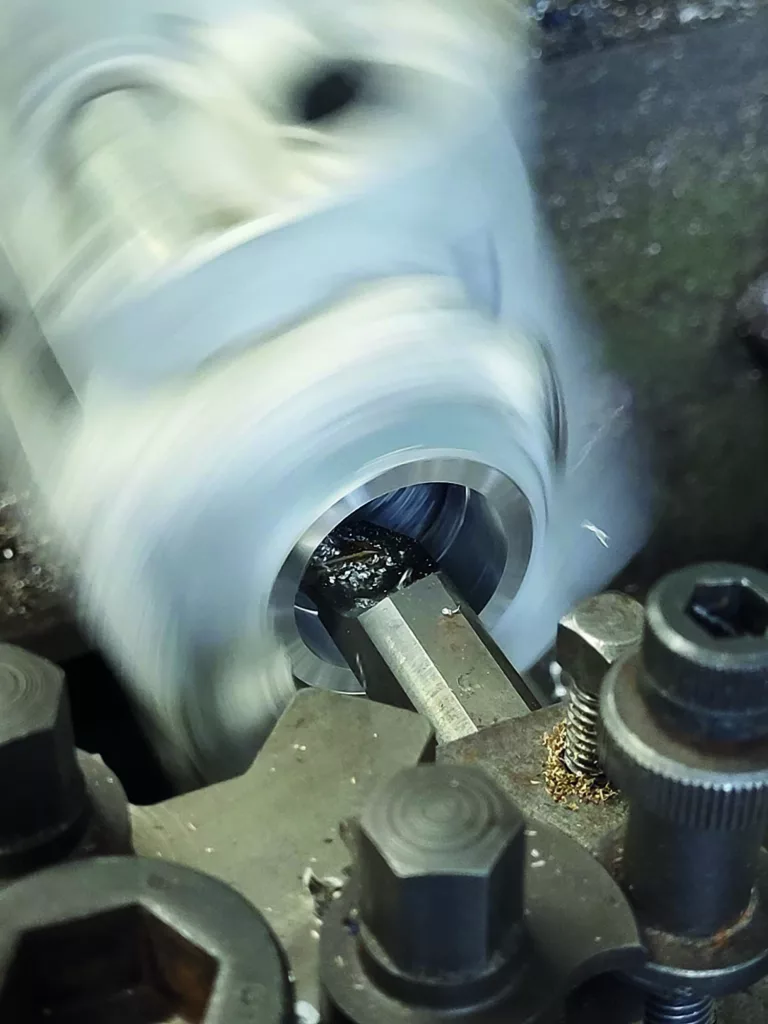

We will remove the existing aluminium collar by machining it away and replace it with a specially machined steel piece that is screwed in the aluminium casing. This new steel collar is then also secured with an invisible locking bolt, at the rear end of the steering box.

This eliminates the risk of the cracks and due to the solidity of this solution, it offers a safe way to refurbish the box. The new collar is then riveted in place and the repair is virtually invisible.

New nut, bushes and seals

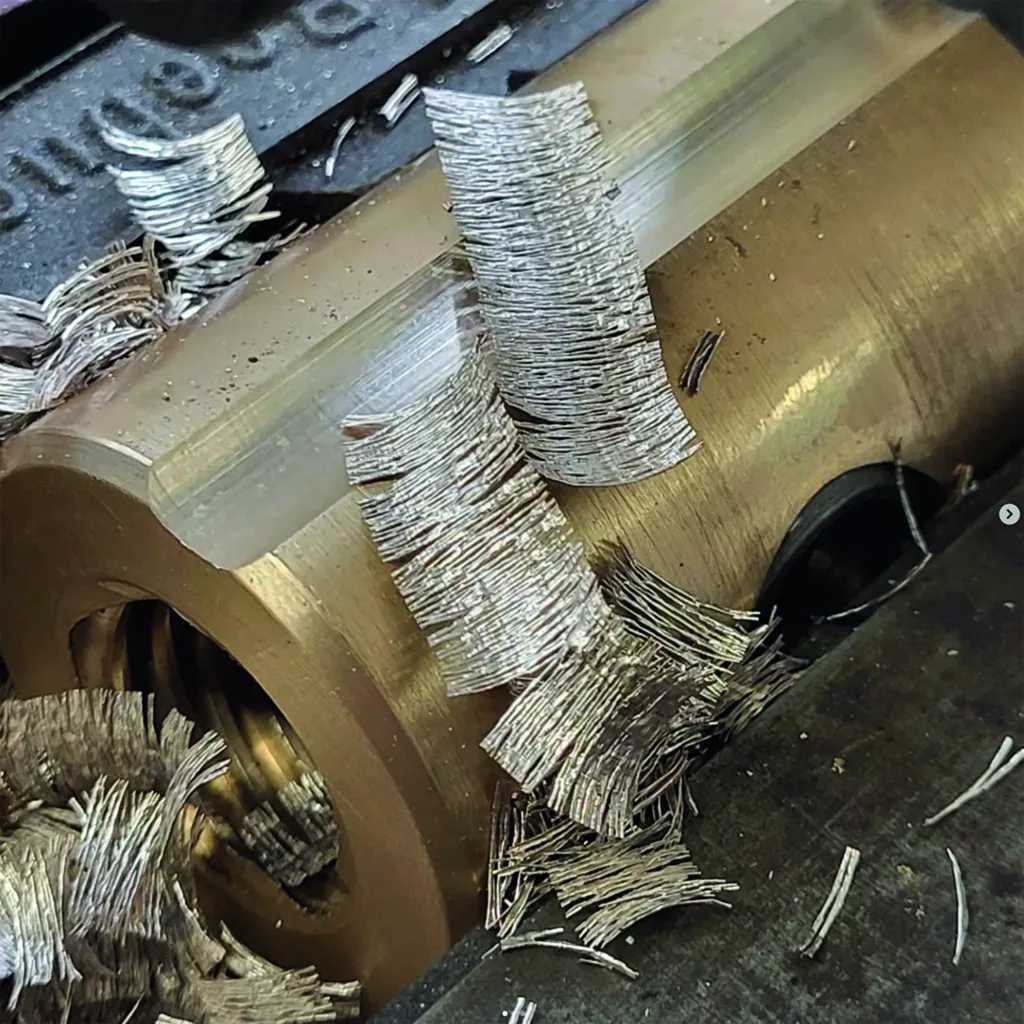

To solve the issue of the excessive play on the steering wheel, the old nut is discarded. The original steering tube (worm) is examined and measured and a new bronze nut is machined to suit the exact thread of this tube.

The new nut will have a longer threaded part, giving it more strength than the old steel nut, where the thread is not running all the way.

By matching a new nut to the existing steering tube or worm, the play is eliminated as much as possible in this design.

In case the aluminium steering box has wear on the inside of the casing, this can be honed as went and the bronze nut will be made up for this exact size.

To complete the overhaul, new bronze bushes are machined, and pressed in the casing and these will be reamed in-line for a perfect fit. The small bearing balls at the top of the steering box are replaced with new ones and will be installed properly greased. A new oil seal is inserted for the rocker arm and the complete box is then assembled and tested to be within the original specs.

All steering boxes will be delivered with complete new seals and are finished in a professional 2K high gloss paint.

Steps

Complete inspection

Disassembly and de-greasing of all components

Sand blasting of casing & parts

Removal of old alu collar and replacement with a new steel insert

Measurement of casing and honing if necessary

Machining of a new bronze nut to match the existing steering worm

Installation of new bronze bushes for the rocker arm + oil seal

Replacement of steel bearing balls at the top and re-assembly of the components

Installation of all new seals and 2K paint finish of the steering box

Can you restore my steering box, what are the costs and how to proceed ?

Normally almost all aluminium LHD or RHD aluminium steering boxes can be restored.

We need following items to be in a good condition to be able to refurbish your box :

– aluminium casing housing should not be damaged, badly corroded or have cracks. Except the top collar which can be replaced..

– the rocker arm inside the box should still be in a usable condition

What is the cost of an exchange refurbished steering box ?

A fully refurbished aluminium steering box, on an exchange basis costs 805€ (excl. VAT).

My casing is still good and I just need a refurbished worm and nut and bushes ?

When the casing and top collar is good and doesn’t need to be machined, an overhaul costs 660€ (excl. VAT)

How to proceed ?

First get in touch with us via mail and we will inform you about shipment of your old box to us. Once we have received your old box we will examine and asses it. Once the status of your old box is established we will send you a payment link for the reconditioned box and a fully overhauled box will be shipped to you.